What is Pebble Stone Plaster?

Pebble plaster, also known as pebble dash or roughcast, is a type of exterior wall finish that incorporates small pebbles or stones into the plaster mixture. It is made from a combination of Natural Pebble Stone and Cement.

The size and type of pebbles used can vary depending on personal preference and design requirements. Commonly used materials for the pebble component include river stones, granite chips, quartzite chips, or other natural stones.

Pebble plaster offers both functional benefits in terms of protection against weathering as well as an attractive aesthetic appeal for external walls. The combination of different-sized stones embedded in the plaster creates a textured finish that adds character and charm to buildings’ exteriors while providing durability against environmental elements.

Why Pebble Stone Plaster / Grit Wash Plaster?

- Hard, crack free surface, which also resists growth of algae and fungus and penetration of water and moisture. Helping greatly in reduction of dampness on wall.

- A great alternative of natural stone for exterior. It’s an economical, long-lasting and maintenance-free plaster.

- You can create aesthetically appealing looks by exposing the aggregate. Expose aggregate is a hardest texture with rich granular effect.

- Pebble crete offers fine exposed-Pebble textured for walls and other vertical features.

The Key Advantages Include

- In situ application- by Company approved applicators.

- A great alternative of natural stone for exterior.

- It’s an economical, long-lasting and maintenance-free plaster.

- Hard, crack free surface, which also resists growth of algae and fungus and penetration of water and moisture.

- Textured yet natural looks

- Customization colour range

- Virtually seamless horizontally, these wall finishes can be done in vertical panels of 1 meter heights.

- Can be wrapped seamlessly around curved details and pillars

- Stonecrete offers fine exposed-aggregate textured for walls and other vertical features.

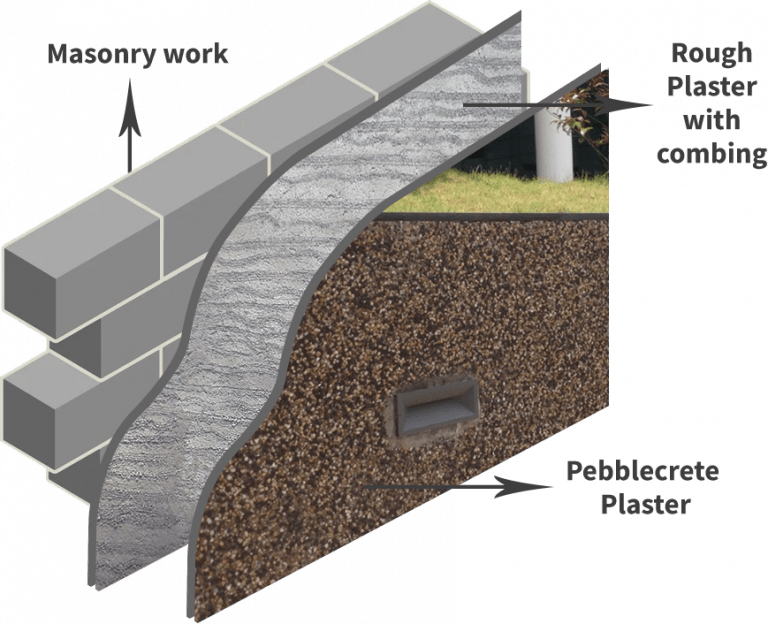

Making Grooves Is Mandatory

12mm Standard Thickness

Surface Preparation : Plaster Surface Requires

- For proper bonding of this product, the plaster should be rough. Marked by combing the surface with wavy lines using a wire brush or nail comb.

- The base should be hard and properly cured for a minimum of 5 to 6 days.

Grey Cement Based Aggregate No. 2

White Cement Based

Grey Cement Based

Pebblecrete For Compound Wall & Planters

Pebble Stone samples